Altana maps Parker Lord's place in a complex value chain network

On Feb. 10, the Parker Lord industrial plant in Saegertown, Pa., suffered a catastrophic explosion and fire that injured dozens. The facility makes adhesives, coatings, and specialty materials for the automotive and other industries, and the damage left executives at automakers and their Tier 1 suppliers scrambling to determine the impact on their operations.

This scenario illustrates a persistent challenge in today's complex automotive supply chains. While OEMs and large Tier 1s typically know their direct suppliers, they often lack visibility deeper into the sub-tier suppliers of critical components and materials.

The Parker Lord facility is a critical node that is likely invisible in traditional supply chain mapping tools, which yield only disparate, outdated data and fail to keep pace with rapidly evolving supplier networks.

Uncovering Hidden Connections with Altana

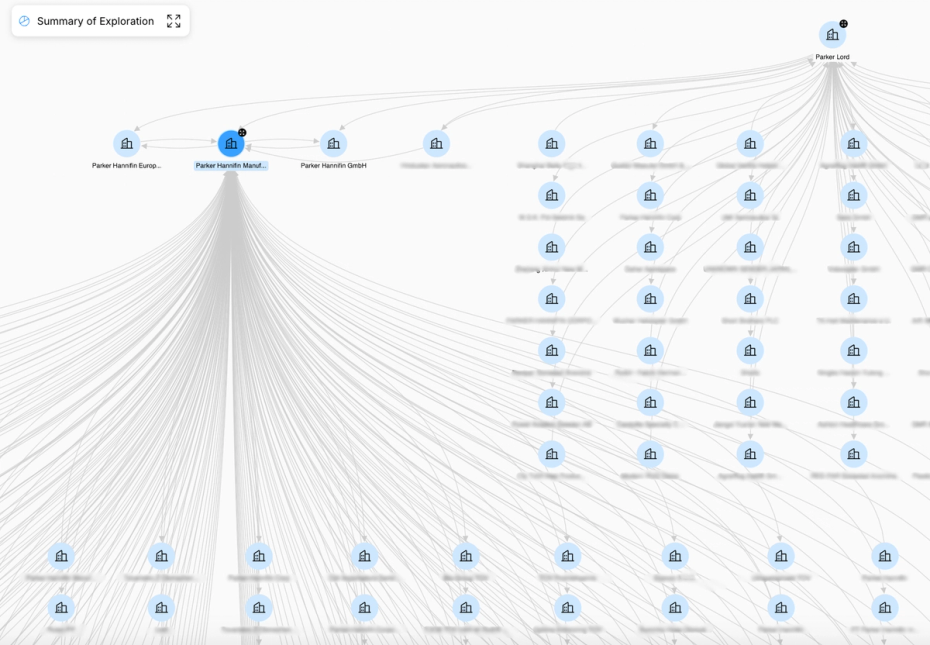

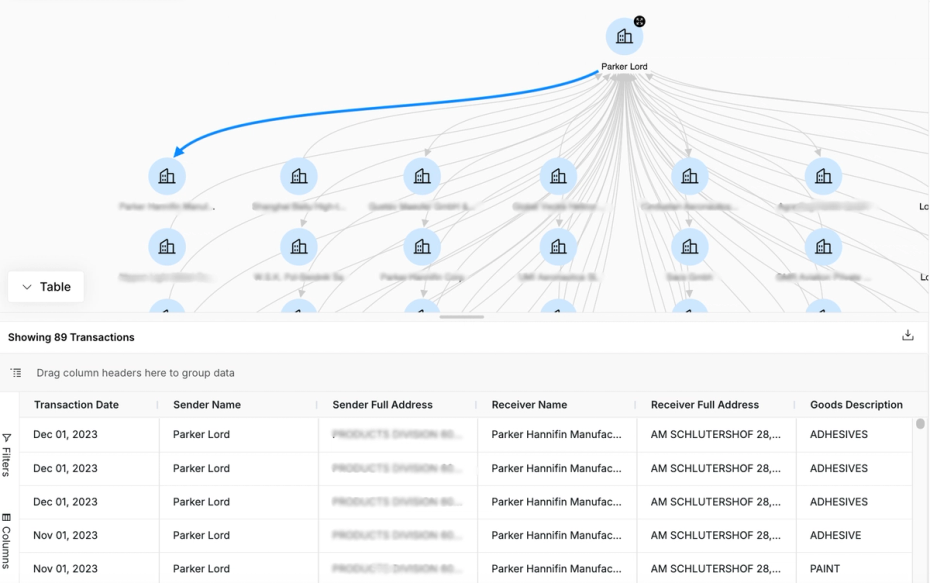

Altana is the only product network connecting buyers, suppliers, logistics providers, and regulators to build more resilient, compliant, and cost effective product lines. The platform combines verified shipment data, procurement records, and corporate information to create deterministic evidence of connections between entities across the entire product value chain.

Altana has the largest, most accurate picture of the global supply chain built from exclusive shipment data. Into that, Altana integrates an automotive manufacturer's own network of Tier 1 suppliers, tracing connections back to upstream facilities like Parker Lord, with greater precision than manual supply chain mapping and surveys. Our AI also dynamically updates customers’ networks as supply relationships and risks change — like if a major manufacturing facility goes offline.

The exploration and mapping of affected value chains gives stakeholders a deeper understanding of their supply dynamics, enabling informed decision-making and effective risk mitigation strategies moving forward.

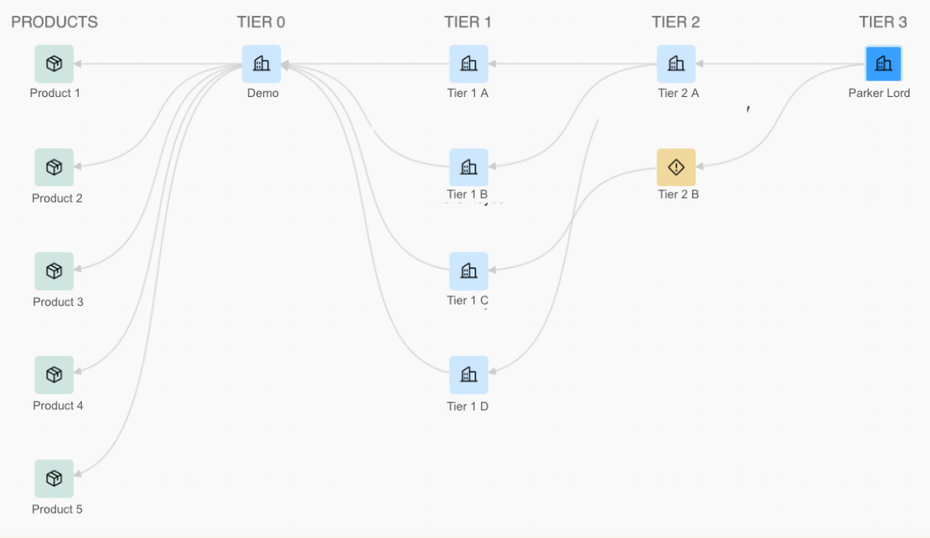

Altana's AI reveals Tier-2 networks

Applied to Parker Lord's Saegertown plant and similar facilities, Altana reveals:

- Direct trading relationships between Parker Lord and downstream customers

- Multi-tier value chain networks that link automotive OEMs to Parker Lord through intermediary suppliers

- Specific components potentially affected by the disruption

From Insight to Action: Managing the Impact

Altana explores the Parker Lord plant's downstream network

Supply Chain Scenario Planning With Altana

- Pinpoint exposure: See the precise share of your product costs impacted by the new tariffs, down to the shipment level.

- Prioritize supplier relationships: Identify which suppliers pose the highest cost risk, so you can execute the right diversification strategy.

- Find alternative sources faster: Search for qualified suppliers outside of affected trade lanes to reduce risk and maintain supply continuity.