Challenge

A global auto manufacturer was facing significant challenges managing its exposure to tariffs. The volatile tariff landscape, including new levies on Chinese goods, expanded tariffs on aluminum and steel, and threatened tariffs on Canada and Mexico, left the company exposed both to direct hits and new costs buried deep within its multi-tier value chains. These costs were largely unseen and unanalyzed.

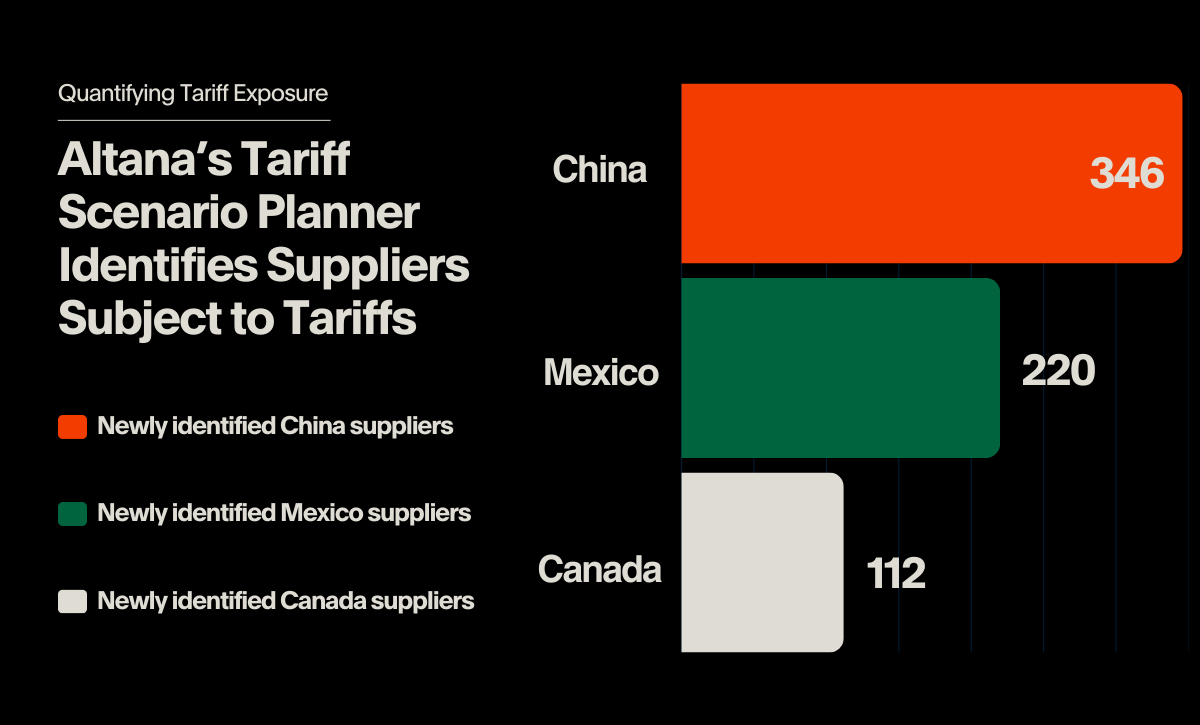

The manufacturer struggled to quantify the extent of exposure to the new tariffs, as most of the impact was concealed in Tier 2 and Tier 3 suppliers. According to Altana's analysis, 98% of automakers' exposure to aluminum tariffs comes from suppliers in Tier 2 or deeper in the value chain. Without comprehensive visibility into these deeper supply chain tiers, the manufacturer could not properly assess financial risks or develop strategies to mitigate them.

Altana Introduces Tariff Scenario Planner as Trade War Rattles World

Learn MoreSolution

- Pinpoint exposure down to the shipment level, giving a clear view of the tariffs’ impact on product costs. This level of detail allowed the manufacturer to see exactly which components and products would be affected by new tariffs.

- Identify high-risk suppliers and quantify their impact on costs. Instead of merely identifying general exposure to non-U.S. suppliers, the manufacturer could see precisely how much of its cost base for each supplier flowed from different countries subject to tariffs. For example, they could determine that 6% of costs for Supplier A came from China to the U.S. in a multi-tier network, compared to 2.5% for Supplier B.

- Search for qualified suppliers outside of affected trade lanes. This capability allowed the manufacturer to reduce risk and maintain supply chain continuity by identifying alternative sourcing options in trade lanes unaffected by the new tariffs.

Impact and Future

Navigate tariff volatility

Quickly quantify exposure to tariffs in your value chains and identify alternative opportunities.