The US Department of Commerce's Bureau of Industry and Security (BIS) has announced a landmark rule that will prohibit Chinese and Russian-made components in vehicle connectivity and autonomous systems. The rule affects all new vehicles sold in the United States, creating an imperative for automotive manufacturers to transform their supply chains.

The Challenge at Hand

The regulation impacts two critical systems in modern vehicles:

- Vehicle Connectivity Systems (VCS): Hardware and software enabling external communication such as Wifi, Bluetooth, cellular and satellite

- Automated Driving Systems (ADS): Software components enabling autonomous operation

The compliance pressure on automotive manufacturers, importers, and suppliers is mounting, particularly since manufacturers begin planning supplier transitions years in advance. Under the rule, companies will have to trace the origins of their components deep into their supply chains while simultaneously tracking software updates and access points throughout their networks.

In the run-up to the final rule’s announcement, BIS noted that the growing complexity of connected vehicle supply chains demonstrates the need for regulation to protect US national security, and the regulation would in turn “incentivize greater supply chain transparency for not only existing supply chains but also for developing supply chains.”

The final rule requires VCS hardware importers and connected vehicle manufacturers to submit Declarations of Conformity once a year to certify compliance. For importers and manufacturers, due diligence to inform these declarations can be conducted independently or through third-party researchers and assessors. However, the rule also includes General Authorizations for certain types of transactions deemed to pose a lower risk.

Value Chain Management: A Strategic Imperative

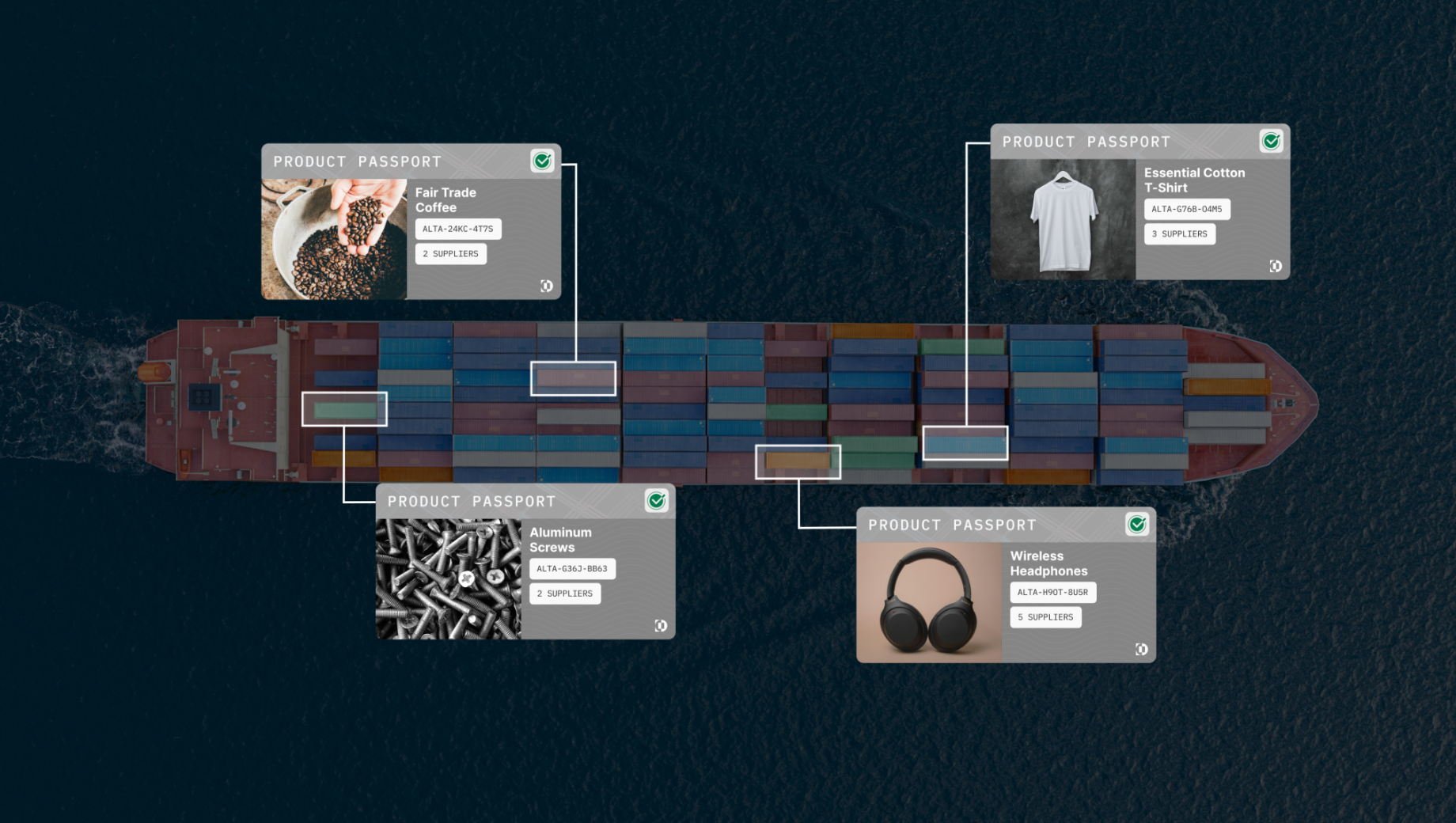

In this technological and compliance environment, real-time visibility into an automotive product or component’s value chain is critical. Using Altana, automotive manufacturers have begun to identify where and how components used within LiDAR systems originate from countries like China and Russia, their sources often masked by intermediaries in other countries.

Altana’s comprehensive approach can transform how manufacturers manage their value chains, allowing them to:

- See across their extended supplier base with unprecedented clarity. Our platform builds an integrated picture of component origins while tracking complex supplier relationships across all tiers, yielding the documentation needed to prove compliance.

- Focus on areas of exposure across your supplier network, delivering contextualized insights that matter. We help identify supplier risks and verify component origins, while supporting compliance documentation.

- Act through our collaborative control tower by designing compliant supplier networks and managing transition timelines, while coordinating with value chain partners. Our platform ensures ongoing compliance monitoring, to create a sustainable approach to regulatory requirements.

A New Level of Visibility and Agility

Altana enables unprecedented visibility, insight, and collaboration from the inside out, beginning with your own data. That allows automotive manufacturers to achieve long-term regulatory compliance across accurate, component-specific value chains, minimizing the impact of supplier transitions on their operations and vehicle programs—even in the face of complex multi-tier supply networks.

Expanded visibility, scenario modeling, and continuous monitoring and updates are crucial for:

- Understanding your extended supplier network beyond your immediate partners and developing effective transition plans well in advance of regulatory deadlines, particularly for identifying Chinese and Russian-origin components in connectivity and autonomous driving systems

- Gathering strategic insight on suppliers, sources of supply and materials, and potential supply chain disruptions, as supply chain and manufacturing operations teams evaluate the impact of supplier transitions on production schedules

As automotive manufacturers navigate this transformative regulation, those equipped with proactive value chain management are best positioned to transform compliance challenges into opportunities for building more resilient, transparent, and secure supply chains.

Moving Forward: From Compliance to Competitive Advantage

While 2027 and 2030 seem distant, longer automotive design cycles demand action now. The connected vehicle security mandate isn't just another compliance requirement—it's an opportunity to transform how automotive manufacturers understand and manage their value chains. Those who move to address these requirements now won't just achieve compliance—they'll build more resilient, transparent, and secure supply networks that provide a competitive advantage in an increasingly complex global market.

Reach out to our team at Altana to learn how we can help you adapt to the connected vehicle security mandate while building a more resilient, transparent, and secure automotive value chain.